What is Salt Spray Test?

What is Salt Spray Test?

Salt Spray Testing (SST) is an accelerated corrosion test that simulates high-salinity environments to evaluate the corrosion resistance of metal materials or surface treatments such as galvanization, electroplating, painting, and anodizing. This test is widely used in aerospace, automotive, marine, electronics, and industrial components to ensure that products maintain functionality and structural integrity when exposed to marine climates in the ocean with salty air or industrial pollution.

Why Conduct Salt Spray Test?

In natural environments, metal materials undergo oxidation reactions when exposed to oxygen, moisture, and salt, leading to rusting or corrosion. These effects are especially severe in marine, humid, cold, or polluted industrial environments. The purpose of the salt spray test is to quickly simulate long-term environmental exposure, helping manufacturers optimize material selection and protective coatings to ensure product durability.

How is Salt Spray Testing Conducted?

Since the salt spray test is designed to evaluate how products or metal materials perform in real-world conditions, creating a realistic test environment is critical. There are two main approaches to salt spray testing:

Natural Exposure Test

This method involves placing products or materials in real-world outdoor conditions and observing their exposure to natural weathering. However, due to uncontrollable environmental variables, this test can take months or even years to yield conclusive results. Therefore, it is mainly used for specific products or field studies.

Artificially Accelerated Salt Spray Test

Artificial testing is conducted in a sealed chamber at approximately 35°C using a 5% sodium chloride (NaCl) solution. The solution is atomized through a specialized tower-type airflow spray system, creating a uniform high-humidity and high-chloride ion environment. This method accelerates the corrosion process, providing faster evaluation results. Testing conditions—such as temperature, humidity, spray duration, and pH value of the solution—are set according to various standards, testing duration ranges from 24 hours to several thousand hours, depending on the application requirements and industry standards. For instance, automotive components may require 240-hour testing, while marine equipment might demand stricter conditions.

| Parameter | Value |

|---|---|

| Sodium Chloride (NaCl) | 5% (g/L) |

| pH | 6.5 - 7.2 |

| Compressed Air Pressure | 1.00 ± 0.01 kgf/cm² |

| Spray Volume | 1.0 - 2.0 ml/80cm²/h |

| Pressure Tank Temperature | 47 ± 1°C |

| Parameter | Value |

|---|---|

| Sodium Chloride (NaCl) | 5% (g/L) |

| pH | 3.0 - 3.2 |

| Compressed Air Pressure | 1.00 ± 0.01 kgf/cm² |

| Spray Volume | 1.0 - 2.0 ml/80cm²/h |

| Pressure Tank Temperature | 63 ± 1°C |

| Parameter | Value |

|---|---|

| Sodium Chloride (NaCl) | 5% (g/L) |

| Copper Chloride (CuCl₂) | 0.26 g/L |

| pH | 3.0 - 3.2 |

| Compressed Air Pressure | 1.00 ± 0.01 kgf/cm² |

| Spray Volume | 1.0 - 2.0 ml/80cm²/h |

| Standard | Issuing Body | Application |

|---|---|---|

| ASTM B117 | ASTM (American Society for Testing and Materials) | Provides guidelines for consistent salt spray testing |

| ISO 9227 | ISO (International Organization for Standardization) | Ensures globally recognized salt spray testing standards |

| JIS Z 2371 | Japanese Industrial Standards | Establishes guidelines for salt spray testing procedures |

| ASTM B368 | ASTM | Specifies conditions for copper-accelerated salt spray testing |

| ASTM G85 | ASTM | Modified salt spray testing for different materials |

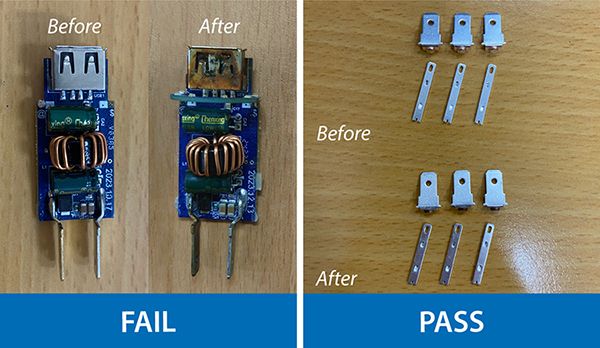

How Are Salt Spray Test Results Interpreted? Are There Grades?

Salt spray test results are usually assessed based on the sample's corrosion condition. There is no exact conversion between test duration and real-world lifespan, as corrosion rates depend on material properties, environmental conditions, and protective coatings. However, approximate estimates can be made:| Test Method | Test Duration | Equivalent Coastal Exposure | Equivalent Natural Exposure |

|---|---|---|---|

| NSS | 1 hour | 5 days | 15 days |

| NSS | 24 hours | 120 days | 1 year |

| Test Method | Test Duration | Equivalent Coastal Exposure | Equivalent Natural Exposure |

|---|---|---|---|

| ASS | 1 hour | 15 days | 45 days |

| ASS | 24 hours | 1 year | 3 years |

| Test Method | Test Duration | Equivalent Coastal Exposure | Equivalent Natural Exposure |

|---|---|---|---|

| CASS | 1 hour | 40 days | 120 days |

| CASS | 24 hours | 960 days | 8 years |

Although salt spray test results provide useful indicators of corrosion resistance, they do not directly translate to real-world durability since environmental factors vary. The test mainly serves as a comparative benchmark for material performance.

Although salt spray test results provide useful indicators of corrosion resistance, they do not directly translate to real-world durability since environmental factors vary. The test mainly serves as a comparative benchmark for material performance.| Corrosion Spread (mm) | Grade |

|---|---|

| None | 10 |

| 0.0 – 0.5 | 9 |

| 0.5 – 1.0 | 8 |

| 1.0 – 2.0 | 7 |

| 2.0 – 3.0 | 6 |

- Video

- Related Products

PD USB 1A+1C Charger

AS238 /AS238-18W

AS238 is 1A1C charger, it is a perfect charger during the transition period of Type A & Type...

DetailsBattery Main Switch (On-Off)

BF441 /BF441A (with AFD)

YIS Marine's Battery Main Switch (On-Off) is engineered for efficient and reliable battery...

DetailsVoltage Sensitive Relay (VSR)

BF451

VSR automatically combines two batteries when charging and isolates two batteries when not charging....

DetailsMini Bus Bars (100A) - (Imperial Threading - Upgraded 2020)

BF471(2020) | BF471M (5P)

Mini busbar with imperial threading screws and studs allows 100A the most. Optional insulation...

Details