Why is a Flange Nut Better than a Regular Nut?

When you're dealing with fasteners in projects ranging from DIY home improvements to electrical installation projects, the choice between different types of nuts might seem like a minor decision. However, selecting the right type of nut can make a significant difference in both performance and longevity, especially in large current electrical connections. Among the various options available, flange nuts have been proven for being more effective than regular hex nuts in certain applications. Here’s a breakdown of why flange nuts outperform standard nuts:

1. Integrated Flange Provides Better Load Distribution

A flange nut has a built-in wide base (the flange) that helps spread the load across a larger surface area. This reduces the risk of damage to the connected parts and increases the nut's holding strength, especially on softer materials.

2. Enhanced Grip and Vibration Resistance

The serrated edge on the flange nut grips better onto surfaces, reducing the likelihood of loosening due to vibrations. This makes them ideal for use in machinery or automotive applications where vibrations are common.

3. No Need for a Washer

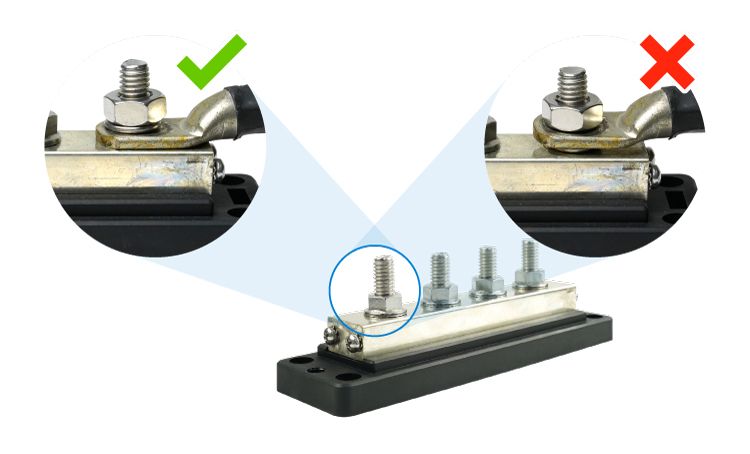

Unlike normal nuts, flange nuts don’t typically require a washer (spring washer or tooth washers). The flange itself acts as a washer, saving both time and material during assembly. This also simplifies the assembly process and reducing installation errors. Below is an example of how using flange nut reduces installation errors: When installing hex nuts with spring washer, one may wrongly install the spring washer in between the ring terminal and the conductors (bus bar), causing large current running trough less conductive spring washers and generate great heat in large current. When using flange nuts there is no need for spring washers and therefore eliminate the possibility of incorrect installation.

Spring washers should NOT be installed between the current conducting parts.

Spring washers should NOT be installed between the current conducting parts.

Removing spring washer by using flange nuts removes the possibility of incorrect installation.

Removing spring washer by using flange nuts removes the possibility of incorrect installation.| Feature | Flange Nut | Normal Nut |

|---|---|---|

| Load Distribution | Excellent due to integrated flange | Requires additional washer for better load distribution |

| Vibration Resistance | Serrated flange prevents loosening | May loosen over time |

| Need for Washer | No | Yes, often needed |

| Surface Protection | Wide flange prevents damage | Dependent on washer and torque |

| Cost Efficiency | More cost-effective in long-term | Higher due to added components |

FAQ

What are the main advantages of a flange nut?

Flange nuts distribute load more effectively, resist loosening due to vibrations, and eliminate the need for washers.

When should I use a flange nut instead of a normal nut?

Flange nuts are ideal for high-vibration environments like automotive and industrial applications.

Do flange nuts cost more than normal nuts?

Initially, flange nuts may be slightly more expensive, but they save costs in the long run by reducing the need for additional washers and lowering maintenance.

Can flange nuts be reused?

Yes, flange nuts can typically be reused, but their serrated edges may wear down over time, reducing their effectiveness.

Are flange nuts stronger than regular nuts?

Flange nuts are not necessarily "stronger," but their design provides better load distribution and stability under stress.

Do flange nuts need washers?

No, flange nuts have a built-in flange that acts as a washer, simplifying the assembly process.

- Related Products

Digital Voltage Sensitive Relay (VSR) with Start Isolation

BF453

The BF453 Digital Voltage Sensitive Relay (DVSR) is designed to enhance battery management...

DetailsMRBF Terminal Fuse Block

BF462

YIS Marine introduces the MRBF (Marine Rated Battery Fuse) Terminal Fuse Block, a compact and reliable...

DetailsDual MRBF Terminal Fuse Block

BF463

YIS Marine introduces the MRBF (Marine Rated Battery Fuse) Terminal Fuse Block, a compact and reliable...

DetailsMini Bus Bars (100A) - (Imperial Threading - Upgraded 2020)

BF471(2020) | BF471M (5P)

Mini busbar with imperial threading screws and studs allows 100A the most. Optional insulation...

DetailsMini Bus Bars (100A) - (Imperial Threading - Upgraded 2020)

BF472(2020) | BF472M (4P)

Mini busbar with imperial threading screws and studs allows 100A the most. Optional insulation...

DetailsCommon Bus Bars (150A) - (Imperial Threading - Upgraded 2020)

BF473(2020) | BF473M (10P)

Common busbar with imperial threading screws and studs allows 150A the most. Optional insulation...

DetailsCommon Bus Bars (150A) - (Imperial Threading - Upgraded 2020)

BF474(2020) | BF474M (4P)

Common busbar with imperial threading screws and studs allows 150A the most. Optional insulation...

DetailsCommon Bus Bars (150A) - (Imperial Threading - Upgraded 2020)

BF475(2020) | BF475M (20P)

Common busbar with imperial threading screws and studs allows 150A the most. Optional insulation...

DetailsCommon Bus Bars (150A) - (Imperial Threading - Upgraded 2020)

BF476(2020) | BF476M (6P)

Common busbar with imperial threading screws and studs allows 150A the most. Optional insulation...

DetailsCommon Bus Bars (150A) - (Imperial Threading - Upgraded 2020)

BF477(2020) | BF477M (12P)

Common busbar with imperial threading screws and studs allows 150A the most. Optional insulation...

DetailsMaxiPower Bus Bar (250A) - (Imperial Threading - Upgraded 2020)

BF478(2020) | BF478M (4P)

Heavy Duty copper bus bars carry current up to 250A

DetailsMaxiPower Bus Bar (250A) - (Imperial Threading - Upgraded 2020)

BF479(2020) | BF479M (6P)

Heavy Duty copper bus bars carry current up to 250A

DetailsUltra Power Bus Bar (600A)

BF481 (4P)

The Ultra Power Bus Bar by YIS Marine is a top-tier solution that combines durability, efficiency,...

Details